I often have to bore using a Jacobs chuck in the tail stock.

One day while marking my drill bit to the right depth it dawned on me that there must be a way to use the quill as a depth gauge.

After inspecting my Jet I noticed that there are graduations on the quill. Ugh! can’t a guy invent anything these days.

But my stubby and small jet don’t have graduations so it was still worthwhile to embark on a design. I wanted something that would work on any lathe, not do any damage and stay out of the way.

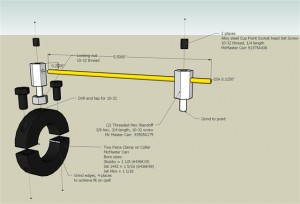

Next I went where I always go when I want to design something conceptually ….SketchUp.

The design uses a collar that clamps on the quill (when it is all the way back) as a base to hold the pointer rod which is made from a brass rod. Threaded hex standoffs are used to clamp the pointer and make the pointer itself. Set screws are used to make the pointer and the pointer rod adjustable. A cheap metal ruler (woodcraft) with a magnet strip CA’d on the back, makes up the dial. Otherwise I think the plan above and the pictures below are somewhat self explanatory.

Below are some pictures of the different setups I used on different lathes. Grinding is necessary on the collar used in the plans for some lathes because the collars don’t come in exact sizes. The rod on the small jet was bent to create the pointer. You will see various pointer configurations in the photos below. Mouse over the picture to see the captions.

Before you ask… I painted my Jet 1442 to match my Stubby 🙂